What’s Involved in An Electrical Thermal Imaging Survey?

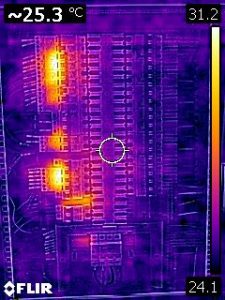

An Electrical thermal imaging survey is a non-evasive and non-destructive procedure using infrared technology.

An electrical thermal imaging survey using a thermal imaging camera can be used on different types of equipment including:

- Busbar systems

- Distribution boards and fuse boards

- High voltage systems

- Transformers

- Control panels

- Batteries

- UPS systems

- Switchgear and switchboards

Using infrared technology on electrical infrastructure is a renowned method of predictive maintenance and when done correctly can be effective at fault finding before equipment failure. Our strict protocols ensure that the faults we document are indeed items that require investigation and possibly remedial work and not simply loaded circuits manifesting temperature.

Our Electrical Inspections involve:

- All panels removed where acceptable, safe to do so and on a Permit to Work basis.

- All electrical equipment inspected have their own individual trend page which includes a thermogram and digital image, ambient, measured and delta T trending of the temperature.

- Trending compares data automatically between inspections. Last four thermograms are included on each page and all trend data is captured and displayed in a table and in graphical format for Measured, Ambient and Delta T (measured/ ambient) to allow for condition monitoring of equipment.

- Detailed fault pages including Load correction formula is utilised during the inspection. Using component rating, actual load, measured temp and ambient temp, the following values are produced:

• Load core temp: estimate of component temp if operating at 100% load.

• Fault severity based on load core temp – ref temp (from BS7671)

• Estimation of maximum amps to apply whilst keeping temperature beneath reference temp (BS7671)